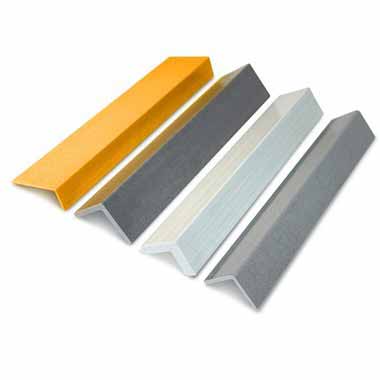

FRP pultruded profiles are currently a widely used material, which can be used to make various products such as guardrails, grilles, cover plates, and square tubes. In the production process of FRP pultruded profiles, different diameters will affect their performance. So for FRP pultruded profiles, what is its diameter requirement, let's find out together.

In the process of producing glass fiber, the diameter of glass fiber can be controlled by changing the melting temperature of glass fiber raw material, hole diameter of bushing plate, wire drawing temperature and wire speed, etc. In the past, glass fibers with a diameter of 9-10 μm were often used as reinforcing materials for composite materials, but now glass fibers with a diameter of 13-18 μm are gradually used.

The thinner the diameter, the higher its strength?

Theoretically speaking, the finer the diameter of the glass fiber, the higher its strength, but in actual production, the strength of the glass fiber is far lower than the theoretical value, which is due to the formation of many microcracks on the surface of the monofilament during the drawing process. The research shows that when the diameter of the glass fiber changes in the range of 9-13 μm, the tensile breaking strength of the high-strength glass fiber precursor remains basically stable.

However, when the diameter of the glass fiber becomes larger, the specific surface area of the glass fiber and its surface activity become smaller.

The amount of adsorbed wetting agent on the surface of the glass fiber is greatly reduced, resulting in a substantial increase in the surface defects of the glass fiber and a decrease in strength. According to the principle of fiber reinforcement, only when the fiber length is above the critical length can the reinforcement effect of the fiber be fully exerted. Theoretically speaking, the minimum length of the reinforcement fiber is 50 to 100 times the diameter. However, as the fiber length continued to increase, the tensile strength decreased significantly.

As the fiber length increases, the fiber reinforcement efficiency increases.

When the fiber length exceeds 12mm, the reinforcement effect of the fiber on the properties of the composite material basically reaches the best. Although as the fiber length increases, the microcracks of the fiber will increase accordingly, thereby reducing the strength of the fiber, but in terms of rigidity, compressive strength, bending strength, creep resistance, impact strength, etc., long fiber FRP is better than short fiber. FRP exhibits better performance. There are three ways for fiber composites to absorb impact strength: fiber breakage, fiber pullout, and resin breakage. As the fiber length increases, more energy is consumed in pulling out the fiber, which is beneficial to the improvement of the impact strength. In addition, the end of the fiber is easy to cause stress concentration, which is the initiation point of crack growth, so long fibers with a small number of ends can also improve the impact strength of the material.