- Product quality has passed ISO, GB/T, EN131, etc.

- Product style supports customized service.

- Provide 24-hour online technical support.

Whatsapp: +8615303735673

E-mail: Jessica@frpzs.com

Whatsapp: +8615303735673

E-mail: Jessica@frpzs.com

Product Details:

FRP deck planks are produced by a pultrusion process. Compared to other materials such as steel and aluminum, pultrusion materials are easier to design, lighter, longer lasting and safer. FRP deck planks have higher corrosion resistance to highly corrosive seawater than other materials such as steel and aluminum.

Thanks to its lightweight, it can be installed smoothly even in remote areas where heavy machinery cannot be used. Our frp deck planks are light but strong enough so there is no need to worry about that heavy vehicles couldn't pass over them.

In the next few years, the boardwalk built by frp deck planks is still beautiful and does not require routine maintenance like other boardwalk materials.

Product Description:

| Specification | FRP Pultruded Floorig Panel Deck Board |

| Production Technique | Pultrusion process |

| Surface Treatment | Smooth,paint or Customer request |

| Material Composition | Fiberglass roving,fiberglass mat,resin,filler |

| Resin Type | Orthophthalic resin(GP)Isophthalic resin(ISO)Vinyl ester resin(VE)Phenolic resin(PH) |

| Surface Material | Polyester mat,Needled mat,Continuous strand mat,Composite mat |

| Application | Aerospace, military, construction, chemical processing, electricity, infrastructure, healthcare, mining, oil extraction, rail transit, parks, exhibitions, transportation |

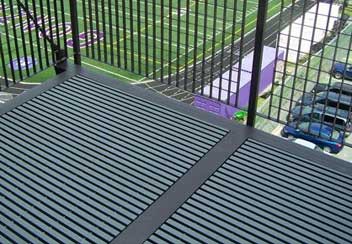

Application Scenarios of FRP Deck

|

|

|

|

|

|

FRP Deck Board Main Features:

Safety: Chemical resistant,anti-conrrosion,anti-alkali,anti-slip,anti-aging,all those traits promises our FRP grating with high safety.

Stability: Expansion and constraction is 24%and 50% less than aluminum and steel ,providing greater dimensional stability.

Durability: Superior durability to stainless steel ,Aluminum,and Galvanized Gratings,especially in highly corrosive environmrnts.

Strength: 50% higher tensile strength than hot rolled steel and better impact resistance.

FRP Deck Board Performance Index:

| Property | TEST Method | Units | Mean-Value lw/cw |

| Tensile Strength | ASTM D638/GB1447--83 | MPa | 210/75 |

| Tensile Modulus | ASTM D638/GB1447--83 | GPa | 10 / 22 |

| Flexural Streng | ASTM D790/GB1449--83 | MPa | 302/76 |

| Flexural Modules | ASTM D790/GB1449--83 | GPa | 18.6/7.2 |

| Compressive Streng | ASTM D695/GB1448--83 | MPa | 258/98 |

| Compressive Modules | ASTM D695/GB1448--83 | GPa | 19.2/7.2 |

| Interlaminar Shea(LW) | ASTM D2344/GB3357--82 | MPa | 24.5 |

| Charpy Impact Strengh | ISO179/GB1451--83 | KJ/m | 279 |

| Barcol Hardness | ASTM D2583 | - | 50 |

| Elongation to break | ASTM D638/GB1447--83 | % | 0.9 |

| Water Absorption(MAX) | ASDN D570/GB1462 | % | 0.57 |

| Density | ASTM D792 | g/cm3 | 1.8 |

| Coefficient of Thermal Expansion | ASTM D696/GB2572--82 | 10-6/ºC | 5.1 |

| ()Flammability Classification | UL94/GB8924--88 | - | VO(32) |

| Tunel Test | ASTM E--84 | - | 25Max |

| Flammability Extinguishing | ASTM D635 | - | self extinguishing |

| Arc Resistance(LW) | ASTM D495/GB1411--78 | /(s) | 120 |

| Dielectric Constant(PF) | ASTM D150/GB1409--79 | @60Hz | 5 |

| Dielectric Strength(PF) | ASTM D149/GB1408--78 | KV/mm | 8 |

| Dielectric Strength(LW) | ASTM D149/GB1408--78 | KV/mm | 1.6 |

| Surface Resistance | ASTM D257/GB1410--78 | Ω | 1015-1012 |

| Volume Resistance | ASTM D257/GB1410--78 | Ω.cm | 1015-1012 |

| Remarks | LW= lengthwise,CW= crosswise,PF= perpendicularlaminate face | ||

Hot Tags: pultruded composite fiberglass reinforced plastic deck, China, manufacturers, factory, price, trench ladder, frp transparent sheet, Carbon Fiber Pultrusion Mold, Fiberglass Step Ladder, frp sheet pile, fiberglass mesh