Consider a CNC cutter with a specialized frp pultruded profile cutter, blade cutting, good cutting, and no flying debris.

If the funds are sufficient, recommend that the source use a vibrator cutter to cut the frp pultruded profile. Note that the general cutter produces large amounts of debris when cutting the frp pultruded profile. This is hard to handle, like a vibrating knife with a small cutting opportunity, Vibrating the cutter up and down will not cause debris to fly around, And the workbench will use vacuum adsorption system, which also effectively prevents the scattering of debris.

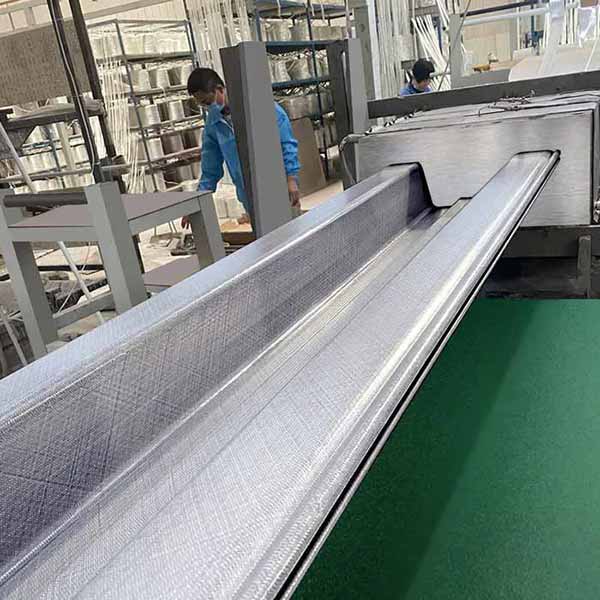

Frp pultruded profile is a kind of inorganic non-metal material with excellent performance. The advantages are good insulation return, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantages are brittle and poor abrasion resistance.

Cutting with grinding wheel cutting machine, the disadvantage of cutting is that the accuracy is not high. If you want precision, you can use CNC cutting machine, frp pultruded profile can use round knife cutting machine, laser cutting machine.

Frp pultruded profile can use shock cutter and laser cutter. Water knife cutting is also possible, round knife, vibrating knife cutting is mechanical cutting. High accuracy, high efficiency, laser is heat cut, The laser tube is as powerful as possible because the frp pultruded profile is resistant to high temperatures. Water cutting is a cold cutting, cutting may have the phenomenon of wool edge, etc.

Select the right device depending on the product you want to do.