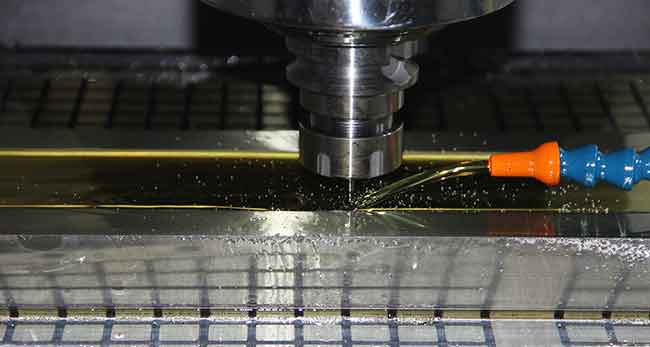

What is Fiberglass Pultrusion Mold?

Fiberglass pultrusion mold is a process of manufacturing fiber-reinforced plastic (FRP) products with constant cross-sections. The term “pultrusion” is a combination of “pull” and “extrusion”, which means the material is pulled through a heated die that shapes it into the desired profile. Fiberglass pultrusion mold can produce various FRP products, such as rods, tubes, beams, channels, angles, and profiles, for different applications and industries.

Why Choose Fiberglass Pultrusion Mold?

Fiberglass pultrusion mold offers many advantages over other materials and processes, such as:

High strength-to-weight ratio: FRP products are lightweight but strong, which makes them suitable for structural and load-bearing applications.

Corrosion resistance: FRP products are resistant to chemicals, moisture, salt, and UV rays, which makes them durable and long-lasting in harsh environments.

Thermal insulation: FRP products have low thermal conductivity and expansion, which makes them ideal for temperature-sensitive applications.

Electrical insulation: FRP products are non-conductive and EMI/RFI transparent, which makes them safe and compatible with electrical and electronic devices.

Design flexibility: FRP products can be customized in shape, size, color, and surface finish, which makes them versatile and adaptable to various needs and preferences.

What are the Applications of Fiberglass Pultrusion Mold?

Fiberglass pultrusion mold can produce FRP products for various applications and industries, such as:

Mass transit: FRP products can be used for canopy framing, flooring systems, seats, and interior panels for buses, trains, subways, and light rails. They can offer safety, lightweight, durability, and strength for mass transportation systems.

Refrigeration: FRP products can be used for structural beams, kick plates, trim pieces, floor and wall systems for refrigerated trucks, trailers, containers, and warehouses. They can offer thermal insulation, corrosion resistance, and hygiene for refrigeration applications.

Automotive: FRP products can be used for bumpers, spoilers, hoods, fenders, and chassis for cars, trucks, motorcycles, and bicycles. They can offer weight reduction, fuel efficiency, aerodynamics, and performance for automotive applications.

Utilities: FRP products can be used for poles, crossarms, ladders, platforms, and enclosures for power transmission and distribution systems. They can offer corrosion resistance, electrical insulation, and weather resistance for utility applications.

Construction: FRP products can be used for window and door frames, decking boards, railing systems, roofing panels, and cladding systems for residential and commercial buildings. They can offer durability, aesthetics, fire resistance, and energy efficiency for construction applications.