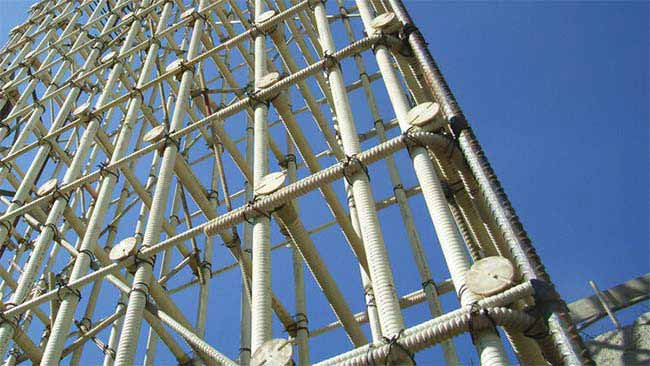

Introduction to Fiberglass rebar

Fiberglass rebar is an anisotropic material made of glass fiber and resin by pultrusion and other methods. Its main function is to replace steel bars as a reinforcing material for cement concrete. The structural shape of Fiberglass rebar is mainly divided into two types, that is, left-handed non-longitudinal rib structure and full helical structure. Left-handed discontinuous ribs with a width of about 2mm are regularly distributed on the surface of the left-handed non-longitudinal structure. The cross-sectional shape is elliptical, and the surface of the full helical structure is a continuous equidistant left-handed or right-handed thread shape, round-headed thread, and the pitch can be determined according to the needs of the engineering structure.

Advantages of Fiberglass rebar

Generally speaking, steel bars can be protected by cement, sand, and stone in alkaline concrete, and have certain durability, but if the concrete coverage is insufficient, the design and construction process are unreasonable, especially In some projects with severe conditions, such as buildings on the seashore that are eroded by salty sea water, dams, bridges and some chemical buildings that are often treated with ice salt and other antifreeze agents for convenient transportation in cold areas, concrete It will suffer from the intrusion of carbides and chlorides, the alkaline concrete will gradually become neutral, and the steel bars will begin to corrode and rust, which in turn will lead to cracking and peeling of the building, eventually causing damage and collapse of the entire building. Compared with steel bars, Fiberglass rebar has excellent characteristics such as high longitudinal strength, corrosion resistance, non-magnetic, fatigue resistance, light weight, and low electrical conductivity. Glass fiber bars have designability of material properties and diversity of structural shapes, and it It is similar to the linear expansion fine number of cement concrete.

Application of Fiberglass rebar

Fiberglass rebar has a wide range of applications in many fields, which are determined based on the characteristics of Fiberglass rebar. The application of Fiberglass rebar in bridge and road engineering is to solve the corrosion problem of steel bars. The use of Fiberglass rebar can greatly reduce corrosion problems and reduce maintenance costs; the application of Fiberglass rebar in concrete structures in offshore areas can avoid chlorides The corrosion of ions can reduce the damage of revetment piles, bearing piles and sheet piles; the application of Fiberglass rebar in low-conductivity and non-magnetic places can play the role of insulation and anti-electromagnetic interference, and it is a lightning protection for airports and military facilities It is an ideal material for interfering interference, and it is also the designated material for MRI devices in many medical and health care departments; the anti-corrosion application of Fiberglass rebar can solve the corrosion problem of steel bars in corrosive environments such as chemical plants and water treatment plants. The salt concentration and carbon dioxide penetration and diffusion in the mud mortar have a high tolerance, which can prevent the corrosion of concrete structures used in harsh environments and improve their durability.

Although Fiberglass rebar is widely used in various fields, the function of reinforcement is directly related to the actual construction status and material quality.

In the future, with the improvement of Fiberglass rebar production technology engineering quality requirements, the service life of buildings will be extended, the manufacturing price of glass fiber and resin will be further reduced, and the competitiveness of Fiberglass rebar in the industry will also increase. more powerful.